Summarized by Howard Velasquez, BS.CE., M.ASCE,

These ISO standards, TR and TS (abbreviated titles) are only a core collection of several hundreds of standards available for the oil & gas industry from ABNT, NSI, API, AS, BSI, CSA, NORSOK, NF, GOST, SAC etc. Some ISO/TC67 standards have been withdrawn and the relevant API standard is referenced above.

These ISO standards, TR and TS (abbreviated titles) are only a core collection of several hundreds of standards available for the oil & gas industry from ABNT, NSI, API, AS, BSI, CSA, NORSOK, NF, GOST, SAC etc. Some ISO/TC67 standards have been withdrawn and the relevant API standard is referenced above.

ISO 10418 Process safety systems (Rev)

ISO 10419 Replaced by API Spec 6AV2

ISO 10423 Wellhead & Christmas tree equipment

ISO 12489 Reliability modeling/safety systems

ISO 13354 Shallow gas diverter equipment

ISO 13533 Drill-through equipment (BOPs)

ISO 13534 Hoisting equipment – care/maintenance

ISO 13535 Hoisting equipment – specification

ISO 13626 Drilling and well-servicing structures

ISO 13702 Control and mitigation of fires and explosions

ISO 13703 Offshore piping systems

ISO 14224 Reliability and maintenance data (Rev)

ISO 14692 GRP piping, Parts 1-4 (Rev)

ISO 14693 Drilling equipment

ISO 15138 Heating, ventilation, and air-conditioning (Rev)

ISO 15156 Cracking-resistant materials for use in H2S environments, Parts 1-3

ISO 15544 Emergency response

ISO 15663 Life cycle costing, Parts 1–3

ISO 16901 Risk assessment in the design of onshore LNG installations

ISO 16903 Characteristics of LNG influencing design and material selection

ISO 16904 LNG Marine Transfer Arms (New)

ISO 17177 Unconventional LNG transfer systems

ISO 17292 Metal ball valves

ISO 17776 Major Accident hazard management during design (Rev)

ISO 17781 Duplex stainless steel materials testing requirements (New)

ISO 17782 Qualification of manufacturers of special materials (New)

ISO 17945 Materials resistant to sulfide stress cracking

ISO 17969 Guidelines on competence for personnel (Rev)

ISO 18683 Systems and installations for supply of LNG as fuel to ships

ISO 19008 Standard Cost Coding System (New)

ISO 20815 Production assurance and reliability management

ISO 21457 Materials selection

ISO 23936-1 Thermoplastics

ISO 23936-2 Elastomers

ISO 27469 Method of test for offshore fire dampers

ISO 29001 Sector-specific quality management systems

ISO 13624 Marine drilling riser systems, Parts 1-2

ISO 13625 Marine drilling riser couplings

ISO 19901-7 Station keeping systems

ISO 10855 Offshore containers, Part 1-3 (New)

ISO 18647 Modular drilling rigs for offshore fixed platforms (New)

ISO 18797-1 Elastomeric coating of risers – polychloroprene or EPDM (New)

ISO 19900 General requirements for offshore structures

ISO 19901-1 Metocean design and operating considerations

ISO 19901-2 Seismic design procedures and criteria (Rev)

ISO 19901-3 Topsides structure

ISO 19901-4 Geotechnical and foundation design (Rev)

ISO 19901-5 Weight control (Rev)

ISO 19901-6 Marine operations

ISO 19901-8 Marine soil investigations

ISO 19902 Fixed steel offshore structures

ISO 19903 Fixed concrete offshore structures (Rev)

ISO 19904-1 Monohulls, semi-submersibles and spars (Rev)

ISO 19905-1 Site-specific assessment of jack-ups (Rev)

ISO 19905-2 Jack-ups commentary

ISO 19905-3 Site-specific assessment of floating units (New)

ISO 19906 Arctic offshore structures

ISO 35101 Arctic Operations – Working environment (New)

ISO 35103 Arctic Operations – Environmental monitoring (New)

ISO 35104 Arctic operations – Ice management (New)

ISO 35106 Arctic Metocean, ice and seabed data (New)

ISO 3977-5 Gas turbines – procurement

ISO 10428 Sucker rods

ISO 10431 Pumping units

ISO 10434 Bolted bonnet steel gate valves

ISO 10436 Replaced by API Std 611

ISO 10437 Special-purpose steam turbines

ISO 10438 Lubrication, shaft-sealing and control-oil systems, Parts 1–4

ISO 10439 Centrifugal compressors

ISO 10440-1 Rotary-type positive-displacement process compressors (oil-free)

ISO 10440-2 Rotary PD packaged air compressors

ISO 10441 Flexible couplings – special

ISO 10442 Integrally geared air compressors

ISO 12211 Spiral plate heat exchangers

ISO 12212 Hairpin heat exchangers

ISO 13631 Reciprocating gas compressors

ISO 13691 High speed enclosed gear units

ISO 13704 Calculation of heater tube thickness

ISO 13705 Fired heaters for general service

ISO 13706 Air-cooled heat exchangers

ISO 13707 Reciprocating compressors

ISO 13709 Centrifugal pumps

ISO 13710 Reciprocating positive displacement pumps

ISO 14691 Flexible couplings – general

ISO 15547 Heat exchangers, Parts 1-2

ISO 15649 Piping

ISO 15761 Steel valves DN 100 and smaller

ISO 16812 Shell & tube heat exchangers

ISO 16901 Risk assessment of onshore LNG installations

ISO 16961 Internal coating and lining of steel storage tanks

ISO 17177 Unconventional LNG transfer systems

ISO 17292 Metal ball valves

ISO 17348 Materials Selection in CO2 Environment for casing, tubing and downhole equipment (New)

ISO 17349 Streams containing high levels of CO2 (New)

ISO 18796-1 Internal coating and lining of process vessels (New)

ISO 18624-1 Design and testing of LNG storage tanks

ISO 20088-1 Resistance to cryogenic spillage of insulation materials – Liquid phase (New)

ISO 21049 Centrifugal and rotary pumps shaft sealing

ISO 23251 Replaced by API Std 521

ISO 24817 Composite repairs for pipework (Rev)

ISO 25457 Flares details

ISO 27509 Compact flanged connections

ISO 28300 Venting of storage tanks

ISO 28460 LNG – Ship to shore interface

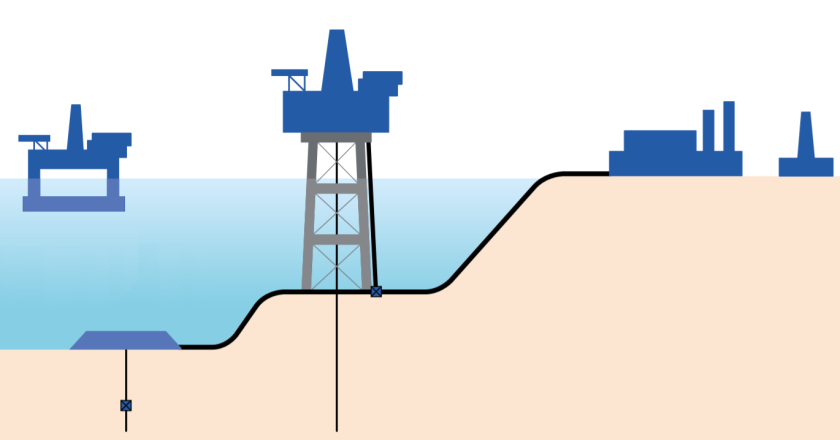

ISO 13628-1 Subsea production systems

ISO 13628-2 Subsea flexible pipe systems

ISO 13628-3 Subsea TFL pumpdown systems

ISO 13628-4 Subsea wellhead and tree equipment

ISO 13628-5 Subsea control umbilical

ISO 13628-6 Subsea production controls

ISO 13628-7 Completion/workover riser system

ISO 13628-8 ROT and interfaces

ISO 13628-9 ROT intervention systems

ISO 13628-10 Bonded flexible pipe

ISO 13628-11 Flexible pipe systems for subsea and marine applications

ISO 13628-15 Subsea structures and manifolds

ISO 10400 Calculations for OCTG performance properties

ISO 10405 Care/use of casing/tubing

ISO 10407-1 Drill stem design

ISO 10407-2 Inspection and classification of drill stem elements

ISO 10414-1 Field testing of water-based fluids

ISO 10414-2 Field testing of oil-based drilling fluids

ISO 10416 Drilling fluids – lab testing

ISO 10417 Subsurface safety valve systems

ISO 10422 Replaced by API Spec 5B

ISO 10424-1 Rotary drill stem elements

ISO 10424-2 Threading and gauging of connections

ISO 10426-1 Well cementing

ISO 10426-2 Testing of well cements

ISO 10426-3 Testing of deepwater well cement

ISO 10426-4 Atmospheric foamed cement slurries

ISO 10426-5 Shrinkage and expansion of well cement

ISO 10426-6 Static gel strength of cement formulations

ISO 10427-1 Bow spring casing centralizers

ISO 10427-2 Centralizer placement and stop-collar testing

ISO 10427-3 Performance testing of cement float equipment

ISO 10432 Subsurface safety valves

ISO 10433 Replaced by API Spec 6AV1

ISO 11960 Casing and tubing for wells

ISO 11961 Drill pipe

ISO 12835 Qualification of casing connections for thermal wells

ISO 13085 Tubing aluminum alloy pipes

ISO 13500 Drilling fluids

ISO 13501 Drilling fluids – processing systems evaluation

ISO 13503-1 Measurement of viscous properties of completion fluids

ISO 13503-2 Measurement of properties of proppants

ISO 13503-3 Testing of heavy brines

ISO 13503-4 Measurement of stimulation & gravel-pack fluid leak-off

ISO 13503-5 Measurement of long term conductivity of proppants

ISO 13503-6 Measuring leak-off of completion fluids under dynamic conditions

ISO 13678 Thread compounds

ISO 13679 Casing and tubing connections testing

ISO 13680 CRA seamless tubes for casing & tubing

ISO 14310 Packers and bridge plugs

ISO 14998 Accessory completion equipment

ISO 15136 Progressing cavity pump systems, Parts 1-2

ISO 15463 Field inspection of new casing, tubing, and plain end drill pipe

ISO 15464 Gauging and inspection of threads

ISO 15551-1 Electric submersible pump systems for artificial lift

ISO 15546 Aluminium alloy drill pipe

ISO 16070 Lock mandrels and landing nipples

ISO 16530-1 Well Integrity life cycle governance manual (New)

ISO 16530-2 Well integrity operational phase

ISO 17078-1 Side-pocket mandrels

ISO 17078-2 Flow control devices for side-pocket mandrels

ISO 17078-3 Latches & seals for side-pocket mandrels & flow control devices

ISO 17078-4 Side-pocket mandrels and related equipment

ISO 17824 Sand control screens

ISO 20312 Design of aluminium drill string

ISO 27627 Aluminium alloy drill pipe thread gauging

ISO 28781 Subsurface tubing mounted formation barriers

ISO 3183 Steel pipe for pipeline transportation systems

ISO 12490 Actuation, mechanical integrity and sizing for pipeline valves

ISO 12736 Wet thermal insulation coatings

ISO 12747 Pipeline life extension

ISO 13623 Pipeline transportation systems (Rev)

ISO 13847 Welding of pipelines

ISO 14313 Pipeline valves

ISO 14723 Subsea pipeline valves

ISO 15589-1 Cathodic protection of on-land pipelines

ISO 15589-2 Cathodic protection for offshore pipelines

ISO 15590-1 Pipeline induction bends

ISO 15590-2 Pipeline fittings

ISO 15590-3 Pipeline flanges

ISO 16440 Steel cased pipelines (New)

ISO 16708 Pipeline reliability-based limit state design

ISO 19345-1 Life cycle integrity management for onshore pipeline

ISO 21329 Test procedures for pipeline mechanical connectors

ISO 21809-1 Polyolefin coatings (3-layer PE and 3-layer PP)

ISO 21809-2 Fusion-bonded epoxy coatings

ISO 21809-3 Field joint coatings (Rev)

ISO 21809-4 Polyethylene coatings (2-layer PE)

ISO 21809-5 External concrete coatings (Rev)

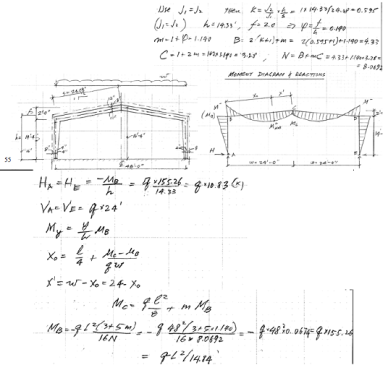

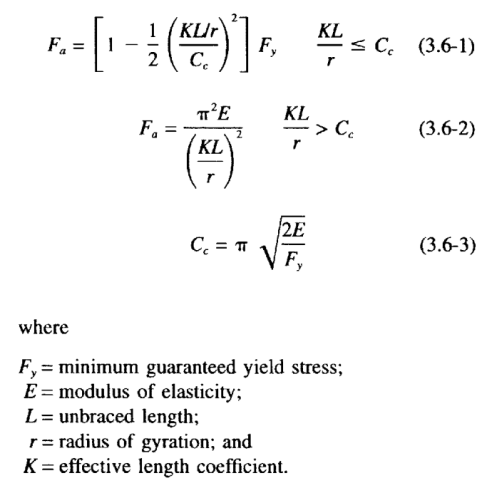

By contrast, senior-level engineers with plenty of experience tend to deal with managerial tasks rather than repetitive computer analysis. Wouldn’t it be great if those who run the software or check the output could quickly verify the results by some approximate hand calculations?

By contrast, senior-level engineers with plenty of experience tend to deal with managerial tasks rather than repetitive computer analysis. Wouldn’t it be great if those who run the software or check the output could quickly verify the results by some approximate hand calculations?